Process Cooling Chiller for Laser Manufacturer

Our Customer, a world leading manufacturer of fibre lasers based in Hampshire, required additional process cooling for a new production unit within their existing facility. The requirement was to provide a cooling capacity for the 30 production lasers used in the process.

The Challenge

The customer had the following requirements from the design and installation of the additional cooling.

Consistent Cooling

To supply a consistent cooling duty for all of the lasers doing testing at the same time.

Sufficient redundant cooling

Sufficient redundant cooling capacity was required in case of unit failure, ensuring resilience. The capacity also provides flexibility for future expansion.

Sensitivity to ferrous materials

A significant consideration in this installation was the sensitivity of our customer’s equipment to ferrous materials.

The Solution

The 2x 150kW chillers are sized to provide 75% of the total cooling requirement in the event of a failure.

A large capacity Weir tank was included in order to accommodate future expansion to the system. This also provides a thermal buffer.

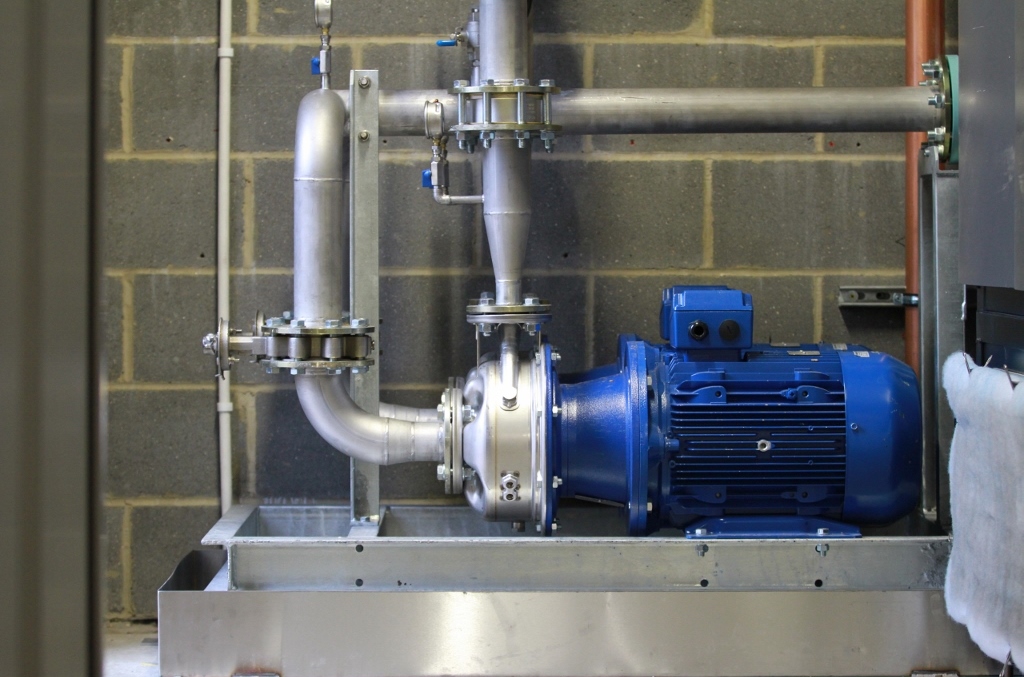

We included a duplex twin pump set, on a run/ standby configuration with auto change over in the event of a failure.

The pumps are inverter controlled using feedback from pressure sensors in the system to regulate the water flow to meet specific demand.

The pipework was installed via “XPress Fittings” which negate the need for any hot works on site.

Routing of the pipework was installed in a reverse return configuration to provide a balanced system giving equal water flow at each outlet.

Find out More

If you have a requirement for a new process cooling chiller or looking for service and maintenance for an existing chiller get in contact with us today using the details below. For further information about our process cooling services, take a look at our dedicated page here.